We take a holistic approach to our design development. From the initial ideas to the final realisation, we accompany the entire process with passion and precision. We use state-of-the-art technologies to quickly transform 2D designs into detailed 3D models. Through simultaneous CAD clay modelling processes, we shorten development times to create more space for creative work on the model.

Our services:

Design

Visualisation

Discover the power of visualisation at am surf – your partner for professional visualisation with leading and standardised software solutions from the industry. Our goal is to create impressive visualisation that is not only aesthetically pleasing, but also facilitates decisions in design development and project implementation.

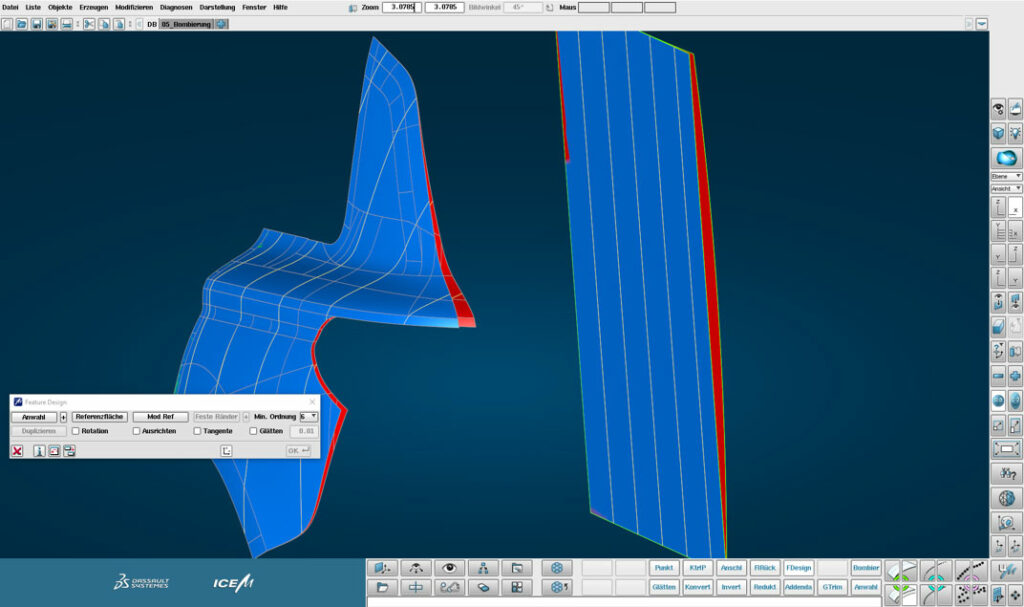

CAD

Our expertise lies in the modelling and representation of design-relevant surfaces. At am surf, we accompany the entire process chain according to our customers’ specifications – from the concept surface to design modelling and Class A series production.

By implementing the simultaneous CAD clay modelling process, we not only achieve shorter development times, but also create more freedom for creative work on the model. This approach enables us to maintain the highest level of quality and creativity in modelling despite shorter time frames.

Claymodelling

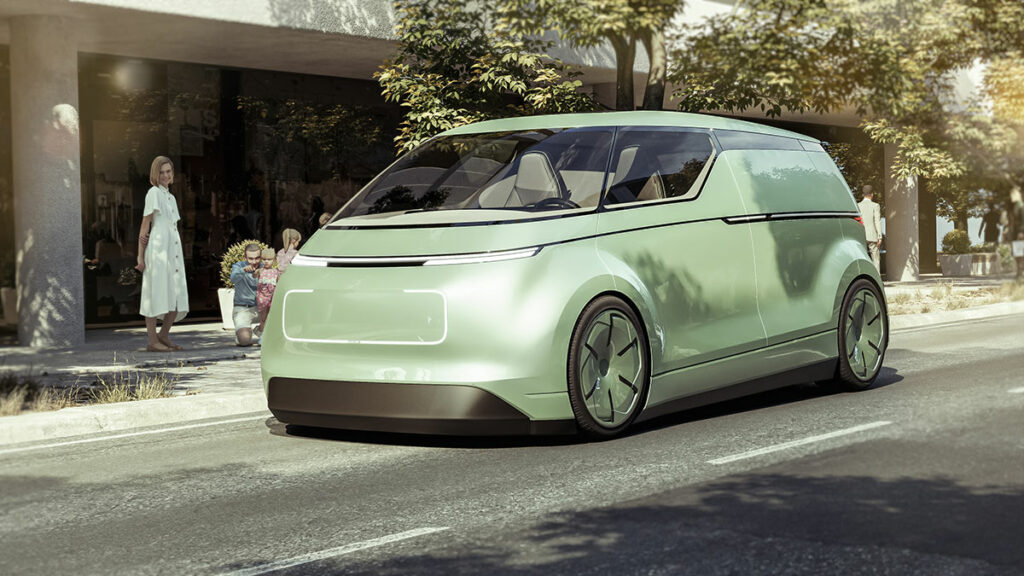

Clay modelling: creative freedom in designAt am surf, we give designers complete freedom to modify surfaces and proportions to achieve the desired design. This creative design freedom is realised in close collaboration with our experienced clay modellers.

The clay modelling process enables engineers, designers, modellers and management to make informed decisions in the design process through visual models. This is crucial to achieving a successful end product.

Whether the clay model is CNC milled or hand moulded, it can be painted and finished with a variety of 3D printed parts. The end result is a model that is often indistinguishable from an actual vehicle. This allows us to make comparisons with different models or an existing production vehicle to better visualise the desired design directions and changes.

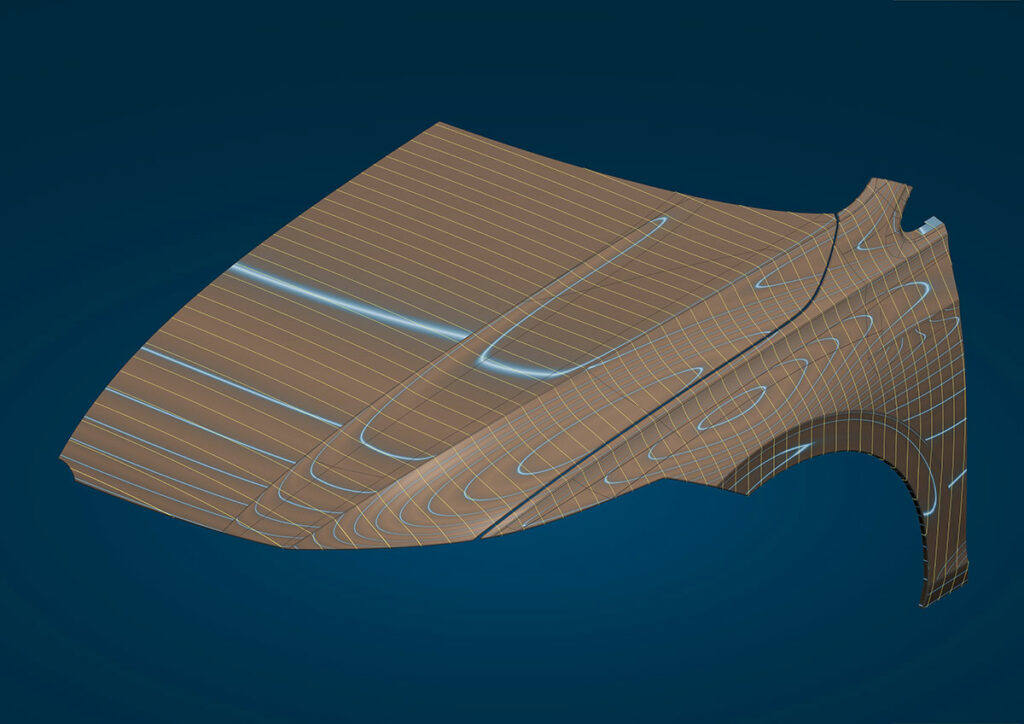

Strake

Innovative strake developments for impressive interiors and exteriorsFor many years, the development of interior and exterior strakes has been one of our company’s outstanding core competences. At am surf, we rely on our extensive expertise to realise all design-relevant surfaces from concept strakes to Class A series strakes. We work closely with the design and construction departments of our clients.

Our experienced strak specialists play an active role in the design-technology convergence process. They carefully analyse the specifications, develop innovative solution proposals and thus make a significant contribution to bringing about well-founded decisions. This close collaboration enables us to create a harmonious interplay between aesthetics and technology.

We utilise the latest and most innovative technologies to ensure that we are always at the cutting edge. In terms of software, for example, we work with programmes such as Icem Surf, Alias, Catia V5 and Grashopper, to ensure the highest precision and efficiency in our steel developments.

Model making

Model making at am surf Modelltechnik:

Innovation and precisionOur process-orientated and innovative building concept creates optimum conditions for first-class model making. With three modelling studios, am surf Modelltechnik GmbH has the capacity to process up to three vehicle models simultaneously. Our high-precision measuring machines are designed for the production of models up to the size of a minibus. All essential equipment and machines for the entire value chain are available directly in our company.

Benefit from our services in model making:

- Proportion models in foam

- Clay modelling

- Clay models with Dynoc or lacquer finish

- Hard modelling

- Hard models, also as see-through models (interior/exterior)

- Feasibility models

- Design experience vehicles

- Light models in original character (with and without function)

- Wind tunnel models

- Ergonomics models

- Design check models

- Exhibition vehicles

- RFM/DKM, interior/exterior

Tooldesign

Tool design: precision right from the start

Our range of services includes the creation and optimisation of tooling designs, the verification of strake data according to production-relevant parameters and the overbombing of strake and design data. We also offer the professional incorporation of pre-stressing and overstressing in accordance with the requirements of production technology.

You can rely on our many years of experience and state-of-the-art facilities to ensure first-class modelling and excellent tool design.